Operational Availability (OA): What It Is & How to Improve It

Keeping equipment running smoothly is at the heart of every successful operation. When downtime strikes, productivity and profits take a hit. That’s where operational availability (OA) comes in—a key metric that shows how reliably your systems are performing. By understanding OA, how it’s calculated, and the factors that influence it, you can take actionable steps to boost uptime, reduce interruptions, and maximize efficiency across your operations.

What Is Operational Availability?

Operational availability, or OA, is a yardstick applied across various industries. It measures how often a system is working compared to how often it should be working.

The OA concept focuses on a system’s uptime. It reveals the amount of time the system is up and running and ready to fulfill its designated function.

OA looks at things that could affect uptime, like breakdowns, maintenance, and repairs. It doesn’t just stop at one factor. As such, it’s an important metric for any business to keep track of.

How to Calculate Operational Availability

People usually express OA as a decimal between 0 and 1. People often convert this into a percentage to make it easier to grasp and understand. Knowing how OA is calculated is helpful.

To find operational availability, divide the average time between maintenance by the total of that time and average downtime.

Operational Availability Formula

The formula looks like this:

OA = Mean Time Between Maintenance (MTBM) / (MTBM + Mean Downtime Time (MDT))

In this equation, MTBM stands for the average duration a system manages to operate as intended. This includes time without encountering a major breakdown that requires repair or other downtime. MDT is the time needed to find a problem, figure out why it happened, and fix whatever is causing the downtime.

By understanding and managing these factors correctly, you can significantly improve the reliability of each critical piece of equipment and its operational availability.

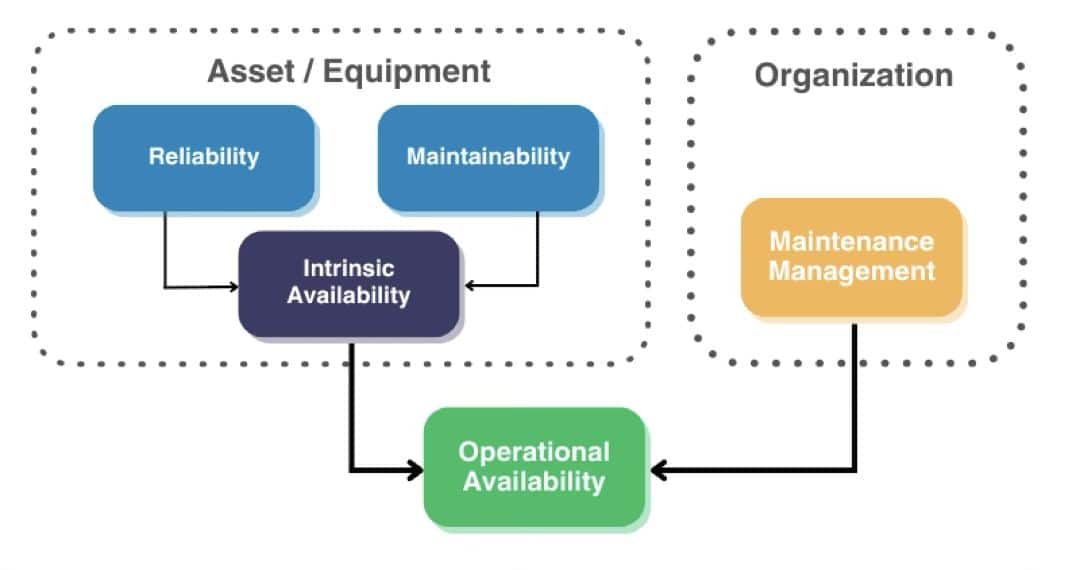

Factors Influencing Operational Availability

Operational Availability Examples

In manufacturing industries, operational availability helps leaders understand how reliably equipment supports production goals. For instance, a food and beverage plant may track OA on its bottling lines to minimize downtime during high-volume runs. In metals or chemical processing, OA highlights how consistently furnaces, reactors, or mixers are available to operate without delays from maintenance or part shortages. In building materials manufacturing, OA can reveal how well saws, presses, or cutting equipment keep up with demand. These examples highlight how OA directly reflects equipment reliability and the overall stability of a company’s operations.

Do You Have Faith in Your Operational Availability?

Operational availability is a complex metric. Because of this, it’s normal to struggle with a few uncertainties. You might feel unclear on how all the puzzle pieces fit together. However, when you realize that OA directly relates to equipment reliability, things start falling into place.

By making sure your machines work well, you can easily create accurate and reliable data for your organization.

Considering things like logistics delays or the availability of replacement parts is important. These issues can be important for your planning and efforts to increase OA in your organization.

Availability Is Equipment Reliability

Why does equipment reliability matter? The answer is simple; a reliable piece of equipment typically results in less downtime. This also means fewer interruptions because of malfunctions, sudden breakdowns, or the frequent need for repair or maintenance.

The outcome of all this is clear. When your system works better, each piece of equipment will have more time to work as it should.

Understanding the connection between OA and equipment reliability can help you appreciate OA more. It can also guide you in taking steps to improve it.

Consider if there are enough repair technicians, parts, or other items available in case there are delays in logistics. Downtime of equipment or systems can impact overall business productivity..

Operation Availability vs. Operating Rate

For efficient and well-informed operations management, knowing the difference between operational availability and operating rate is important.

OA helps you know when your system is ready to work versus when it should be working. Overall Equipment Effectiveness (OEE) measures the time your system is operational and performing its intended function effectively.

The operating rate looks at the gap between what your system is capable of and what it is actually doing. It reflects your system’s actual output efficiency.

The operating rate measures how well your system performs at full capacity. It ensures that your system is reaching its maximum potential.

While OA is about uptime, the operating rate focuses on operational efficiency. These two different and distinct components are equally important in understanding the overall performance of your systems.

Identifying Causes of Instability in Operational Availability

Finding out why OA is unstable or unreliable is crucial for making it better. Planned or unexpected downtime can significantly affect your OA.

This downtime could stem from equipment malfunction or inefficient maintenance strategies. It can also stem from logistics delay that makes replacement parts or other important maintenance components unavailable.

Understanding these factors and how they relate can help guide your OA improvement efforts.

Improving Operational Availability with Digital Work Instructions & Connected Worker Software

Some traditional methods for improving operational availability can include regular team meetings, employee training programs, and the manual tracking of performance metrics. While these methods have their merits, they can often be time-consuming and prone to human error.

Digital work instructions and connected worker technologies can streamline and make these processes more efficient. A “connected worker” uses digital tools and technology to track and handle various improvement methods more efficiently.

By using technology to streamline tasks, a connected worker can easily find information, communicate instantly, and track performance effectively. Digital transformation improves efficiency, reduces errors, and creates a more productive workplace.

Maximize Operational Availability with CAI Software Solutions

Maximizing operational availability requires tools that simplify workflows, enhance communication, and provide real-time insights. With Parsable digital work instructions and connected worker software, frontline teams can capture and analyze data on-site, track key metrics, and respond to issues quickly. This technology helps organizations streamline operations, reduce downtime, and improve overall equipment reliability.

Ready to enhance your operational availability? Contact CAI Software today to see how Parsable can empower your workforce, optimize performance, and drive measurable results.