Understanding Barcodes in the Food Industry: How GS1-128 Barcodes Enhance Traceability

In today’s fast-paced food industry, keeping track of products from production to distribution is more important than ever. Ensuring that your products are properly labeled, easily scanned, and traceable is key to providing the best possible service to your customers. At CAI Software, we understand how overwhelming the barcode world can seem, but we’re here to guide you through it. So, let’s dive into how GS1-128 barcodes (also called code 128 barcodes) can take your business to the next level.

What Exactly Are Barcodes?

Barcodes enable scanning, helping businesses improve efficiency and reduce errors in shipping, pricing, and inventory management. The most widely recognized barcodes include:

- GTIN-12 (UPC): Commonly used in retail for scanning items at checkout.

- GTIN-14: Found on product cases, identifying items during shipping and warehousing.

Why Traceability Matters (And How Barcodes Help)

In the food industry, traceability is like a safety net. Whether you’re dealing with a product recall, ensuring food safety, or simply wanting to provide transparency to your customers, traceability is crucial. Many companies still rely on human-readable information, such as printed lot numbers, but this doesn’t allow for quick and easy scanning. For true efficiency, you need that information encoded in a barcode.

And that’s where the GS1-128 barcode comes in.

What Is a GS1-128 Barcode?

A GS1-128 barcode is a powerful tool that can encode multiple pieces of information into one barcode, making it an ideal solution for industries requiring detailed traceability.

Think of GS1-128 as a multi-tasker: it allows you to scan a product and capture multiple pieces of information at one time. For example, based on the segments imbedded into the barcode, you can immediately know where it came from, when it was made, and which batch it belongs to. You can manage inventory efficiently, respond to issues swiftly, and ensure your customers get safe, high-quality products every time.

How Many Digits Is a GS1-128 Barcode?

The length of a GS1-128 barcode depends on the number of segments and the amount of data encoded within each segment. The typical GS1-128 barcode can vary in length but usually contains at least 14 digits (for the GTIN-14) and can extend to include additional segments useful for traceability or billing such as the lot number, serial number, weight and a date (a production date or date of expiry).

How Does GS1-128 Work?

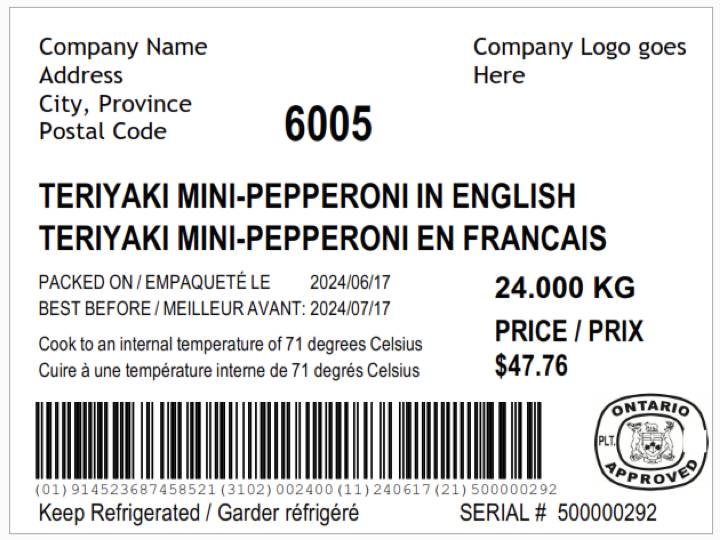

The GS1-128 barcode is a segmented barcode, meaning it contains different pieces of information within one scannable code. Each segment is represented by a specific application identifier (AI), which defines the type of information included, such as product code, lot number, or expiration date. While there are 99+ possible segments for products across all industries, let’s break down the ones commonly found on food items:

- (01): This segment contains the GTIN-14, which identifies the product itself — much like a typical shipping barcode.

- (11): This segment holds the production date.

- (13): This segment is for the packaging date.

- (15): This segment is for the expiry date. (typically, a GS1-128 has one of the possible date segments)

- (10): This segment is the lot number, one of the most important fields for traceability.

- (21): This segment is for a serial number. Some food items have unique case weights so are assigned a serial number.

- (310*): This segment is for weight in kg (the * tells you how many decimals)

- (320*): This segment is for weight in lbs (the * tells you how many decimals)

The beauty of this system is that you can scan the barcode and retrieve all this information in one go. And the best part? The human-readable information is printed below the barcode for those times when you need to quickly glance at the details.

GS1-128 in Action: An Example from the Food Industry

Imagine you’re shipping a case of sausage to a grocery store. The GS1-128 barcode on the box might include the following segments:

- (01): The GTIN-14 product code, identifying the sausage type and supplier.

- (11): The date the sausage was produced on.

- (3102): The weight in kg to two decimal places

- (21): The lot number, enabling traceability back to the batch.

With a single scan, you or your customer can tell the product, it’s weight, packaging date and serial number — a win for both efficiency and customer satisfaction.

The Difference Between GS1-128 and GTIN-14

Both GS1-128 and GTIN-14 barcodes serve important roles in product identification and traceability. The key difference lies in their functionality:

- GTIN-14: Used to identify product cases and identify the company that labelled the product. GTIN-14 focuses on basic product identification and is commonly pre-printed on shipping boxes. It includes a supplier prefix and is helpful for ensuring the correct product is shipped; but, it does not contain information helpful for traceability like lot or serial numbers or a date.

- GS1-128: This barcode can encode not only the GTIN-14 product identifier but also additional traceability data, such as serial numbers, lot numbers, and dates. GS1-128 is essential for industries that need to track products throughout the supply chain.

Why GS1-128 Beats GTIN-14 for Traceability

While GTIN-14 barcodes are great for identifying products in shipping, they don’t carry the extra traceability information that GS1-128 does. If you’re serious about traceability — and we know you are — upgrading to GS1-128 will give you more control over your supply chain and allow you to meet ever-growing industry standards. Some labels will contain both a GS1-128 AND a GTIN-14, in case your customer has a program that is only interested in product codes.

Making GS1-128 Work for You

If your business is in the food industry and isn’t yet using GS1-128 barcodes, it’s time to consider making the switch. The barcode allows for more efficient tracking, helps you meet industry traceability standards, and supports the entire supply chain’s ability to track and manage product information. Not only will this streamline your internal processes, but it will also provide peace of mind for your customers, knowing that your products are fully traceable back to you.

The Bottom Line on GS1-128 Barcodes in the Food

The GS1-128 barcode is a game-changer for traceability in the food industry. It allows you to seamlessly track products, enhance efficiency, and meet industry regulations. By embracing GS1-128, you’ll not only improve your internal processes but also create a more transparent, trust-driven relationship with your customers.

At CAI Software, we believe that every step you take toward improving traceability is a step toward building a better, safer, and more efficient food supply chain. And we’re here to support you every step of the way — from scanning systems to software integration.